祝贺吴凡等同学的文章

“Enhancing interfacial synergies for the preparation of high mechanical strength and interconnected porosity of alumina extrudates through pre-wetting method”

被 Micropor. Mesopor. Mat. 接受发表!

Abstract

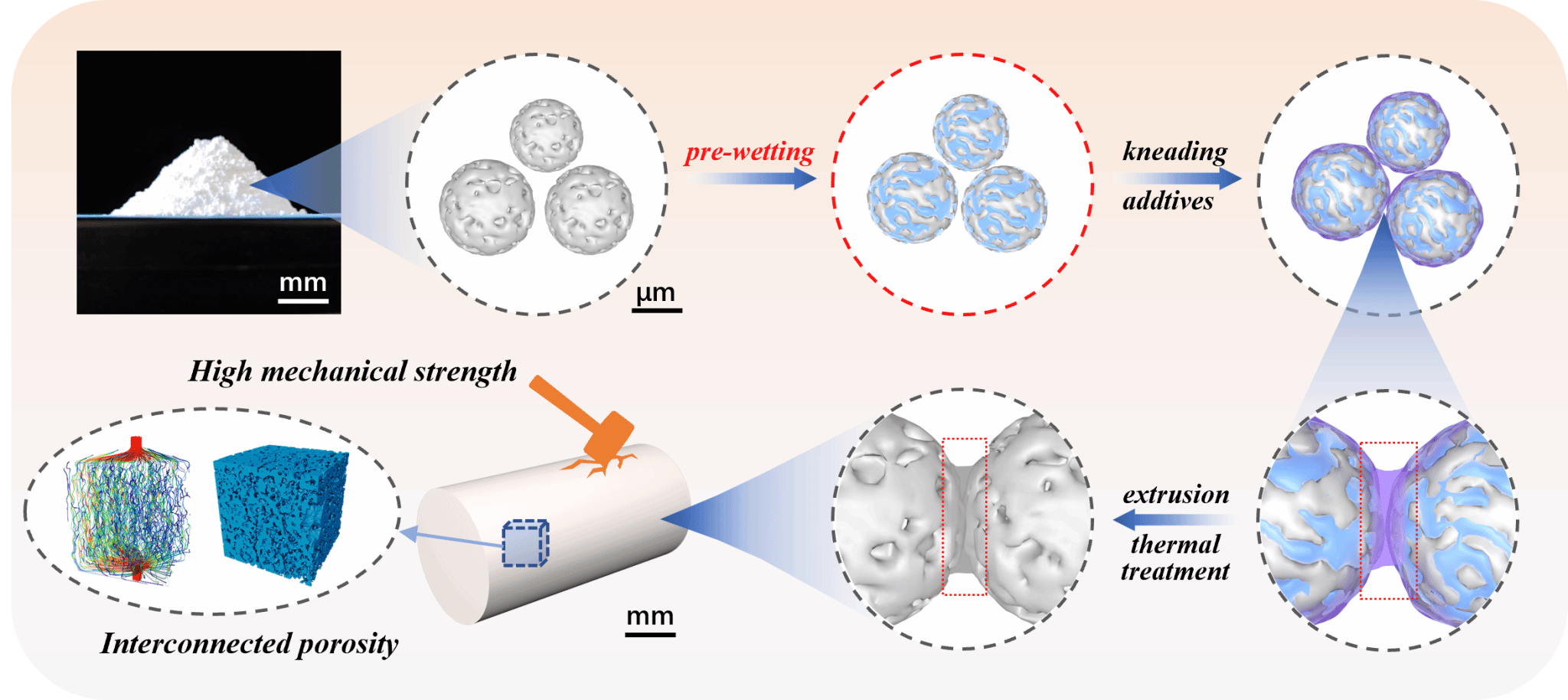

The forming of catalyst supports is a crucial step in the application of industrial catalysts. Alumina, a widely employed catalyst support, is often shaped using nitric acid as a peptizer to enhance mechanical strength. However, the use of large amounts of nitric acid typically results in a decrease in specific surface area and damage to the pore structure due to chemical corrosion. In this work, we present a more practical approach that is pre-filling the open pores of pseudo-boehmite powder with water instead of directly filling them with nitric acid solution. The binder with a small quantity of nitric acid plays a synergistic role in functioning as a glue on the particle surfaces. And through this method, high-strength (231 N·cm-1) alumina support can be prepared more efficiently through extrusion. Besides, the pore structure of the extrudates was characterized by multi-scale methods, including nitrogen physical sorption and XRM (X-ray microscopy), which revealed abundant interconnected hierarchical pores deriving from the pre-wetting shaping process. This proposed approach enables the attainment of high mechanical strength and interconnected porosity for alumina extrudates with less use of acid, which holds a significant practical application value.