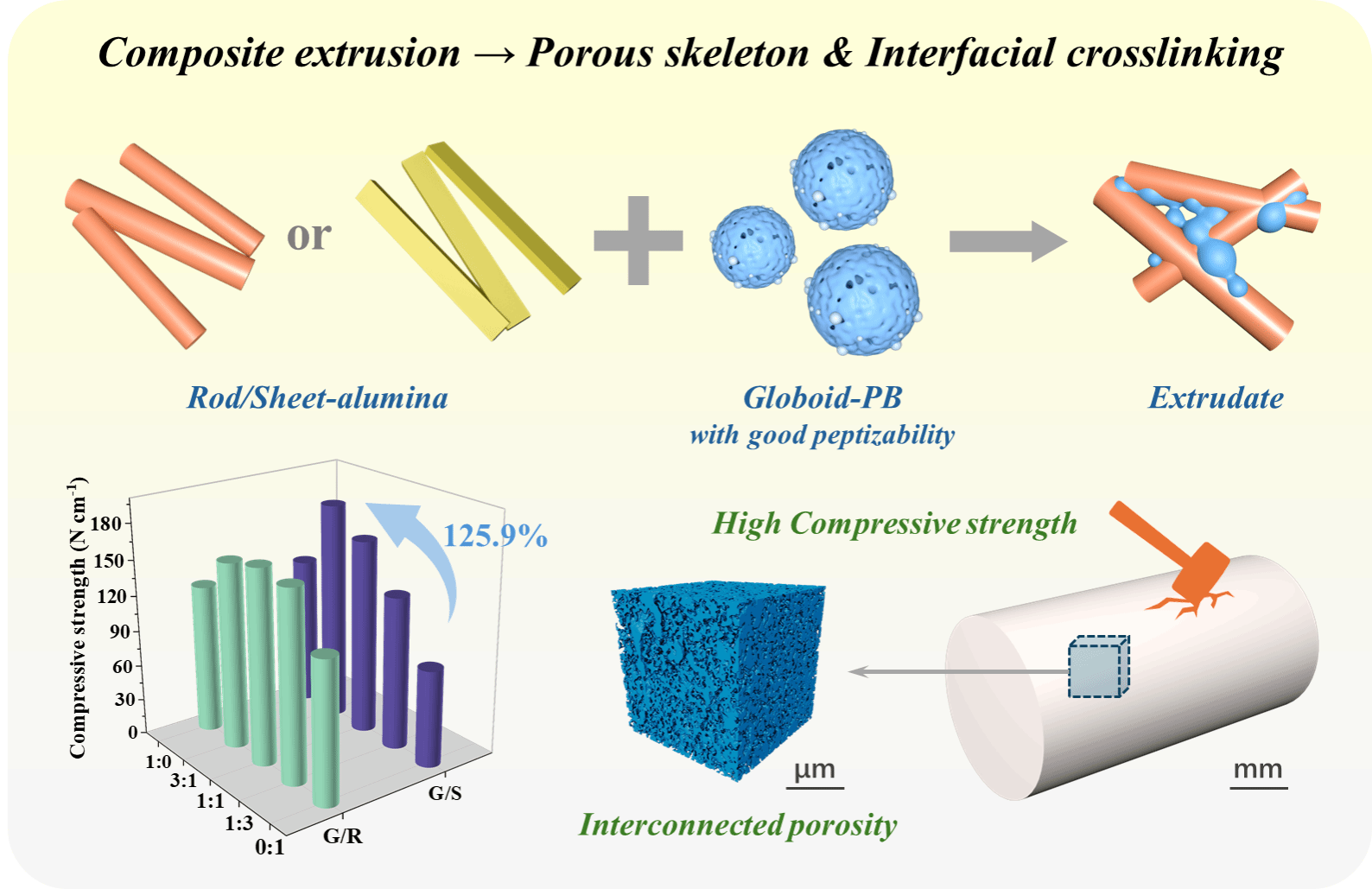

Enhancing mechanical strength and porosity of alumina extrudates through composite processing

Abstract

Industrial alumina supports need to possess both high mechanical strength and porosity, but these requirements often conflict with each other. In this work, differences in powder properties such as particle shape, flowability, and peptizability were utilized to composite for extrusion. When globoid pseudo-boehmite was composited with sheet-like alumina at a mass ratio of 3:1, the extrudate exhibited a mechanical strength of 183 N·cm-1 and a porosity of 62.24%, representing a 46.4% and 4.5% increase, respectively, when compared to using globoid alone. Multiscale characterizations revealed that the composite extrudate possessed rich and interconnected mesopores and macropores. The outcome of DEM indicated that the composited extrudates had higher porosity and particle average coordination numbers than the single powder extrudates. This study revealed a correlation between powder properties and extrudate structures, providing design insights for the targeted control of mechanical strength and pore structure.